-

-

About Unitech

Offering industrial enterprises top-tier products in operational safety interlocking and intelligentization

-

-

-

Products

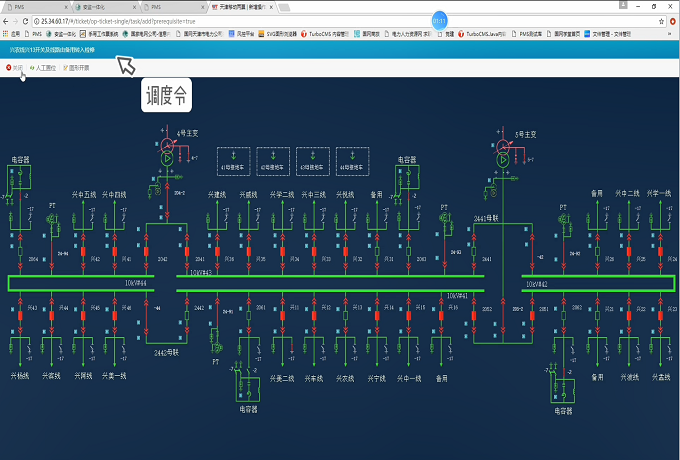

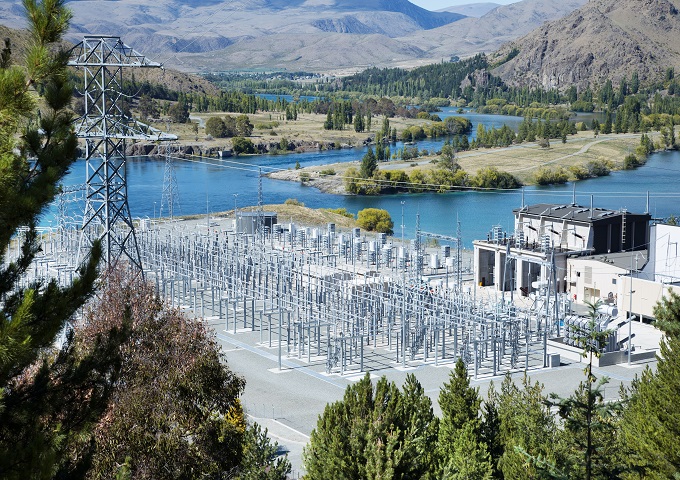

JOYO-B4 Advanced minicomputer-based anti-misoperation integrated operation system UT-F500Z Microcomputer electric anti-misoperation system for intelligent substations UT-F600B Safety management and control system for substation operation and inspection UT-F700Z Integrated intelligent anti-misoperation system UT-F700X Digital two-ticket system JOYO-J Centralized control anti-misoperation integrated operation system UT-F600P Safety management and control system for distribution network operation UT-F500P1 Voltage detection interlocking system UT-F600D Safety management and control system for power generation enterprises UT-F600S Safety management and control system for petrochemical power supply UT-F600S2 Safety management and control system for petrochemical process UT-F600M Safety management and control system for electric operations of coal mine JOYO-H Rail transit power supply operation and safety production management system JOYO-H1 Depot maintenance safety interlocking management system UT-F600H3 Crew scheduling management system UT-0400 Intelligent ground wire management system UT-050 Intelligent key management system UT-7710 Intelligent safety tool management systemJOYO-A Substation integrated automation system UT-Z300D New energy automation system JOYO-F/K petrochemical dispatching and centralized control automation system JOYO-A1 One-click sequence control system for substations UT-Z300S Secondary intelligent monitoring system JOYO-H2 Visual catenary grounding management system UT-Z300B Integrated automation system for intelligent substation UT-P100C2 Campus energy efficiency management system UT-P100C7 Integrated energy O&M systemSolutions

Operation Safety Management and Control Solution for Thermal Power Enterprises Operation Safety Management and Control Solution for Hydropower Enterprises Intelligent O&M Management Solution for Centralized Control of New Energy Wind Farm Intelligent Management and Control Solution Intelligent Management and Control Solution for Energy Storage Stations Centralized Photovoltaic Comprehensive Monitoring Solution Distributed Photovoltaic Comprehensive Monitoring Solution Comprehensive Automation Solution for Booster Stations Online Oil Monitoring Solution for Wind Turbines Online Tower Monitoring Solution for Wind TurbinesDigital Two-Ticket Solution Comprehensive Digital Safety Management and Control Solution for Substation Disconnector Operations Panoramic Digital Anti-Misoperation Solution for Centralized Control Safety Management and Control Solution for Substation Operation and Inspection Comprehensive Intelligent Anti-Misoperation Solution for Substations Intelligent New Electrical Anti-Misoperation Operation Solution for Substations Digital Twin 3D Anti-Misoperation Solution for Substation Operation and Inspection Microcomputer-based Solution for Preventing Electrical Misoperation in Substations Substation Maintenance Topology Anti-Misoperation Solution Comprehensive Automation Solution for Substations Comprehensive Automation Solution for Intelligent Substations One-Click Sequence Control Solution for Substations Disconnector Double-Confirmation Solution for Substations Intelligent Monitoring Solution for Secondary Equipment Intelligent Auxiliary Control Solution for Substations Intelligent Warehouse Management Solution Online Microenvironment Monitoring Solution for Substation Equipment 3D Digital Twin Application Platform Solution for Substations Power Equipment Temperature Monitoring Solution Intelligent O&M Solution for Substation Batteries Intelligent Wearable System Solution for Substation Operation and Inspection Intelligent Inspection Solution for Substations One-Click Sequence Control Video Double-Confirmation Solution for Substations Substation E-Key Access Solution Substation Door Control Solution Communication Interface Lock Control Management Solution for Substation Equipment RoomsNew Distribution Automation System Solution New Autonomous Distribution Transformer Area Solution New Distribution Feeder Automation Solution New Substation/Station House Automation Solution for Distribution Safety Management and Control Solution for Distribution Networks Intelligent Grounding Wire Management Solution for Distribution Networks Distribution Network Voltage Detection Interlock Anti-Misoperation Solution Distribution Network Lock Control Solution Intelligent O&M Solution for Distribution SubstationsIntelligent O&M Management System Solution for Petrochemical Electrical Systems Petrochemical Electrical Automation Control Solution Comprehensive Automation Solution for Petrochemical Electrical Systems Safety Management and Control System Solution for Petrochemical Electrical Operations One-Click Sequence Control System Solution for Petrochemical Electrical Systems Petrochemical Electrical Intelligent Inspection System Solution Safety Management and Control Solution for Petrochemical Process Petrochemical Energy Isolation Management System SolutionRail Transit Power Supply Operation Safety Management System Solution Visual Grounding Solution for Rail Transit Catenary Systems Visual Isolation Grounding Solution for Rail Transit Catenary Systems Visual Grounding Solution for Rail Transit AC Catenary Systems Safety Interlocking Management System Solution for Depot Maintenance Crew Scheduling Management System SolutionIntelligent Campus Intelligent Control Solution Intelligent Campus Dual Carbon Management Solution Energy Efficiency Management Solution for Industrial Enterprise Campuses Intelligent Microgrid Coordinated Control Solution Comprehensive Energy O&M Solution for Industrial Enterprise Campuses O&M Control Solution for Industrial Enterprise Campus Power Distribution Intelligent Campus Lighting Solution Campus Office Lock Control Solution Campus Dormitory Lock Control Solution

-

-

-

Support

One-stop services throughout the entire lifecycle

-