-

-

About Unitech

Offering industrial enterprises top-tier products in operational safety interlocking and intelligentization

-

-

-

Operation and Inspection Safety Management and Control Platform Primary and Auxiliary Monitoring Platform Youan Domain Lock and Control Platform Comprehensive Intelligent Electrical Operation and Maintenance Platform Youke Large Model Platform Youheng Microservice Technology Platform Youhui IoT Platform Youheng Video Analysis Platform Youheng Digital Twin Platform APP PlatformSubstation operations safety management and control system Power generation operation safety management and control system Distribution Network Operation Safety Management and Control System Petrochemical Power Supply Safety Management and Control System Railway Power Supply Safety Management and Control System Coal Mine Power Supply Safety Management and Control System Dispatching Integrated Control Automation System Substation Monitoring System Power Grid Lock Control System IoT Lock Control System New Distribution Network Automation System Intelligent patrol system Auxiliary monitoring system Smart Campus System

Smart terminal

Anti-misoperation Smart Lock Maintenance Smart Lock Intelligent Anti-misoperation Host Computer Key Device Transmission Adapter Intelligent Ground Wire Management Device Key Management Device High-Voltage Voltage-Detection Device Intelligent Safety Tool Management Device Remote Interlock Device Item Management Device Intelligent Ticket-Generation DeviceDynamic Environment Monitoring Devices Fire Information Transmission Control Device Security Monitoring Device Wireless Aggregation Device AI Edge Gateway Device Battery Monitoring Device Oil monitoring device Partial Discharge Monitoring Device Digital Metering Device Smart Wearable Device Intelligent Video Analysis Device Oil Chromatography Online Monitoring System Acoustic Online Monitoring System for Power Equipment Circuit Breaker Intelligent Transfer Cart Distributed Optical Fiber Temperature Sensing System Circuit Breaker Mechanical Characteristic Monitoring Device Passive Wireless Temperature Monitoring Device

-

-

-

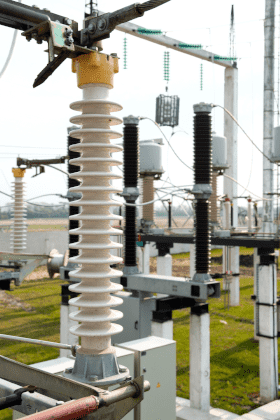

Intelligent Power Generation

Online Tower Monitoring Solution for Wind Turbines Online Oil Monitoring Solution for Wind Turbines Distributed Photovoltaic Comprehensive Monitoring Solution Centralized Photovoltaic Comprehensive Monitoring Solution Intelligent Management and Control Solution for Energy Storage Stations Intelligent Microgrid Coordinated Control Solution Intelligent O&M Management Solution for Centralized Control of New EnergyIntelligent Substation

Intelligent Safety Tool Management Solution for Substations Intelligent Key Management Solution for Substations Intelligent Ground Wire Management Solution for Substations Substation-Wide Locking Control Solution One-Click Sequence Control Video Double-Confirmation Solution for Substations Intelligent Inspection Solution for Substations Intelligent Wearable System Solution for Substation Operation and Inspection Intelligent O&M Solution for Substation Batteries 3D Digital Twin Application Platform Solution for Substations Intelligent Warehouse Management Solution Intelligent Auxiliary Control Solution for Substations Intelligent Monitoring Solution for Secondary Equipment Disconnector Double-Confirmation Solution for Substations One-Click Sequence Control Solution Comprehensive Automation Solution for Intelligent Substations Comprehensive Automation Solution for Substations Microcomputer-based Solution for Preventing Electrical Misoperation in Substations Comprehensive Intelligent Anti-Misoperation Solution for Substations Safety Management and Control Solution for Panoramic Substation Operation and Inspection Panoramic Digital Anti-Misoperation Solution for Centralized Control Digital Two-Ticket SolutionIntelligent Distribution

Rail Transit

Crew Scheduling Management System Solution Safety Interlocking Management System Solution for Depot Maintenance Visualized Three-Position Isolation and Grounding Operation Management Solution for Overhead Contact Lines Visual Grounding Solution for Rail Transit Catenary Systems Rail Transit Power Supply Operation Safety Management System SolutionIntelligent Campus

Iron and Steel Metallurgy

Intelligent Tower

-

-

-

Support

One-stop services throughout the entire lifecycle

-